1984 Anderssons Såg och Bygg AB was founded by Stefan Andersson, they sold building materials and carried out construction activities.

2001 The company was sold, and the new owner was Birger Andersson, who together with the old owner has continued to run the company. Today, the company is mainly active in construction in Luleå, Boden and Piteå Municipality.

The company currently employs between 16-25 year-olds. Its activities are mainly aimed at private, small and medium-sized enterprises and public institutions. We also work as UE for other companies Examples of such companies are Friginor, Luftfartsverket, Luleå Kommun, Nåiden etc.

Today, the company can offer all types of construction services, and also takes on general contracting where cooperation with local UL enables a complete solution.

We also offer laying and finishing of bathrooms, etc. in tiles and clinker.

Andersson Bygg AB is located in Sandnäset, 18 kilometres outside the city, where both the warehouse and the office are located in the same building, which brings great synergies. A small disadvantage is that we are located slightly outside the city centre which means slightly longer transport.

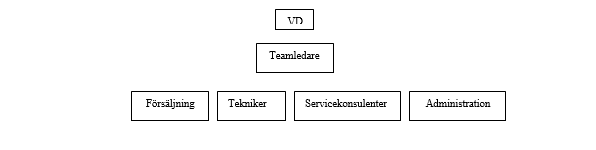

Anderssons Bygg AB is currently owned by Stefan and Birger Andersson, who also work as CEO.

Other partners are Jonathan Sundholm, Anders Broström, Fredrik Vesterberg, Gustav Esberg

We are located outside the city.

We are not subject to any specific laws other than normal environmental laws, we do not produce any environmentally hazardous material.

Environmentally hazardous waste must be disposed of and used in accordance with applicable laws. Through cooperation with Rang-Shells, OCAB, etc., we will keep up to date on changes in laws and requirements regarding waste/production and environmental impact.

Prior to any start of construction, the company, in consultation with Rang-Shells staff or equivalent, shall carry out an environmentally appropriate demolition/construction waste plan.

This plan shall include information on:

-material types

-quantity of material

-special types of materials

-transportation

-ev, transport permits

Documentation of this plan can be added to the environmental plan if the client so wishes. The environmental manager ensures that the plan is documented and verified before it is included in the environmental plan.

The customer’s requirements in terms of waste/materials and products shall be ensured through continuous updates and through internal training.

Customers demand that we use few consumables, environmentally friendly materials and minimise transport.

In January 2003, the management decided to implement an environmental management project that would result in compliance with the ISO 14001 environmental standard.

We will analyse the activities we carry out and their environmental impact. Regarding our suppliers, we will prioritise those suppliers who are actively engaged in environmental work; those who are not engaged in environmental work or have no plans to do so will not be approved suppliers.

Furthermore, the company must carry out the work in the best possible way, taking into account the requirements of the client.

We will review documents, conduct interviews with both decision-making staff and those working closest to the client. Customers and staff will be informed of the ongoing work as it progresses.

The staff concerned must be kept up to date on the requirements for materials/products in terms of environmental impact by means of internal training.

All those who will be working on a specific object must be informed of the requirements/counterchecks to be carried out for the execution of the object before the work begins.

This is done through a consultation prior to the start of the work, minutes and verification of this must be added to the environmental plan by the environmental officer.

The environmental manager or, on his/her advice, a person familiar with the site, shall ensure that all new personnel are made aware of this information before they are allowed to carry out work in the specific site.

We are located in Luleå. Most of the work is done in Luleå, but there may also be work in Boden and Piteå and the surrounding area.

We have no major emissions from production, either to water or air, because we handle pre-produced packaging.

In the projects carried out by the company, proposals for an environmental plan must be drawn up in consultation with the client.

–

We use very few oils, chemicals or other environmentally hazardous products in our operations. Where such materials are nevertheless used, they shall be disposed of and submitted for recycling in such a way as to minimise the impact on the environment.

When vehicles are serviced, they are handed in to a garage as far as possible.

We do not use any water in production, only for our own consumption, the detergents used in the dishwasher etc. are swan-labelled.

Offices and warehouses are heated by direct electricity; otherwise, only office machines and lighting use electricity.

Electricity consumption is documented.

For some specific contracts, electricity consumption is also documented.

–

We only handle products that are packaged by the supplier, where we set requirements for the materials in the packaging and the contents. At our request, the material supplier must be able to declare the goods and ensure the environmental impact of the material with documentation. Such documentation must include information on the name of the product, the manufacturer and the declaration of contents of the product.

When choosing between two materials, the most environmentally friendly material should always be used, even if it is more expensive.

Contracts where the project is to be environmentally declared, this must be done with “documentation goods/products”.

Such documentation shall include:

-Product name and manufacturer.

-The location of the material/product in the object.

-quantity.

This documentation must be compiled in a final documentation after the end of the project. The final documentation shall be submitted to the client after the compilation has been completed.

Wide range of recyclable products.

Requirement that selected suppliers comply with the laws and requirements. Staff at the workplace must be able to carry out their work in accordance with the company’s environmental and waste management objectives, with the help of briefings and internal training.

–

Chemicals and hazardous substances are only used to a small extent for own consumption, a list of all substances is available and is reviewed every year in the context of internal control.

In the case of contract work, the client’s environmental studies and any environmental programme shall form the basis for the handling of waste.

The environmental plan is drawn up on the basis of the client’s requirements for the specific object.

In addition, a separate waste study must be carried out at the design stage of each contract, and this must be well understood by all those who will be working on the contract when it is reviewed prior to the start of work.

Auditing of the environmental plan must be carried out continuously during the contract, in order to ensure that the environmental plan is followed. In the event of an error detected during an audit, this must be documented on a “non-conformance report/audit environment”. Documented deviations must be entered in the environmental plan.

Staff concerned must document the goods/products in the project by means of self-checking.

The documentation shall be carried out in and verified by means of a “documentation/review environment”.

This self-checking must be carried out during both demolition and construction works. Particular care should be taken when dealing with hazardous waste/goods. Any deviations found during self-monitoring must be compiled in an “deviations report/re-inspection environment”, which must be submitted to the environmental manager on an ongoing basis, who must revise the environmental plan after the inspection and, with proposals for measures, ensure that these are carried out immediately. Verification of the proposed measure must be entered in the environmental plan by the environmental manager after implementation.

Documentation of self-monitoring must be combined with the environmental plan.

Furthermore, the company shall not work with waste or products that may harm personnel or the environment, and shall engage the services of an expert and competent body/company for this purpose. The demands on our subcontractors must be of the same nature as we demand of our own company. Any deviation from our environmental plan by a subcontractor must be immediately reported to the subcontractor’s environmental manager. These deviations must be documented on the “deviations/re-inspection-UE”, and our environmental manager must ensure, with the help of the client’s requirements, the UE supplier’s environmental manager, that the proposed measures are followed and documented.

Verified documents are added to the environmental plan by the environmental officer.

Leftover products are handed over to the recycling station. Documentation of these materials must be available.

–

The emissions that can occur are from cars during transport. To some extent, emissions to the environment may occur from the use of materials packaged in spray cans.

When choosing a product, where there is an option of a product packaged in another way, it should be chosen in the first place, unless the investigation maintains otherwise.

Deliveries are made by coordinated deliveries to customers.

Coordination of staff to and from work takes place to the greatest extent possible.

Despite coordination much car transport for staff we try to reduce .

Does not occur, swan labelled hygiene products are used.

Fluorescent tubes, batteries, chemicals, and other materials designated as hazardous waste are sorted and delivered to the environmental station.

In the event of the presence of “hazardous” waste in works, this should be addressed at the earliest possible stage. The aim is to track “hazardous” waste at the design stage. The occurrence of “hazardous” waste must be documented on the form “documentation/hazardous-waste/material” and included in the waste report provided to the contractor. Particular care must be taken when drawing up the environmental plan, even when there is only a suspicion that “hazardous” waste may be present in the contract.

The occurrence of “hazardous” waste during an ongoing contract shall lead to an audit of the already established “documentation/hazardous waste/materials”, the environmental manager shall ensure that the audit is carried out and documented on the “audit hazardous waste/materials”. This will also be the basis for an update of the waste study. The environmental officer ensures that the update is carried out using the “hazardous waste/materials audit”.

In the case of construction work, material for protection measures in the event of accidents and incidents in the event of contact/work with environmentally hazardous waste/materials must be available in the sheds and vehicles at the workplace.

Examples of what this material should contain:

-eye shower

-information on procedures

-first aid material

Well, soft plastics, metal, wood, etc. are sorted and sent for landfill and recycling to municipal facilities.

Demolition and landfill waste should be sorted as far as possible and not sent unsorted in any case.

Metal is sorted and sent to companies that buy the material in the first instance or recover it for recycling in the second instance.

All waste parts are sorted today

Part of the packaging is part of a return system

Suppliers are also required to ensure that the packaging is such that the goods delivered are not damaged. Materials delivered to the workplace must be packaged in such a way that the condition of the goods does not deteriorate. Secondly, the goods must be delivered in such conditions that they can be handled by personnel at the workplace in such a way that no damage occurs.

Where the product is available in specific formats, the format best suited to the specific characteristics of the object should be ordered in order to achieve the minimum waste of material and environmental impact on nature.

In contracts where materials and products must be declared, this must be done with a so-called environmental goods documentation.

The documentation shall include information on:

-product name

-manufacturer

-table of contents

The environmental manager ensures that this documentation of goods/products is compiled in a final documentation which is submitted to the client after completion of the project.

Small company with little chance of getting the requirements implemented.

Works where noise may or may not occur for a certain period of time shall, in agreement with the client’s requirements and wishes, be carried out in such a way as to cause the least possible disturbance.

Any restrictions or requirements must be written into the health and safety plan. These restrictions must be well understood by the personnel concerned, as well as by any subcontractors, before the work begins.

No in-house production, which means that everything is manufactured and packaged by suppliers. Assessment of suppliers’ environmental awareness is done through questions and also in some cases visits to the supplier. Suppliers are then ranked, with priority given to the most environmentally conscious.

The suppliers used must be able to demonstrate the content of the goods by means of documentation.

5% of the transport is carried out by our own fleet and 95% by external transport companies. Some of the transports are coordinated for the delivery of goods.

Demolition and construction waste should only be transported to approved waste disposal sites. If the client wishes, these transports must be verifiable by means of transport documents and a receipt.

The environmental manager must ensure that this is followed by means of a transport document/receipt and, after checking, verify this on the environmental plan.

Any authorisation to transport special waste should preferably be granted during the design phase. Acquired permits, documented, verified and added to the environmental plan by the environmental officer.

Where coordination of supplies and services works, environmental impact is reduced

Difficult to measure and evaluate when so many cars are driving back and forth.

Coordinate deliveries with special delivery car. Reduce the number of purchasing occasions for as many continuous material deliveries as possible.

5:13 Education

Relevant personnel within the company shall be continuously informed about requirements/laws with the aim of improving environmental awareness.

Information/documentation should be produced at the design stage of the works with regard to the environmental and impact requirements of the works.

This information/documentation must be communicated to all personnel who will be involved in the work prior to the start of the work.

The information as well as the requirements/laws must be available to everyone in the workplace.

Offices and warehouse are located in the same building. The stock consists of very small volumes.

Andersson Bygg AB is located in Sandnäset, 18 kilometres outside the city, where both the warehouse and the office are located in the same building, which brings great synergies. A small disadvantage is that we are located slightly outside the city centre which means slightly longer transport.

Anderssons Bygg is the local construction company with broad expertise and long experience. We offer services in all areas of construction, from new builds to renovations and extensions.